Recommendation Info About How To Control A Motor

6 hours agothe aim of preventive motor maintenance is to minimize operational problems and assure that the motor continues to work properly.

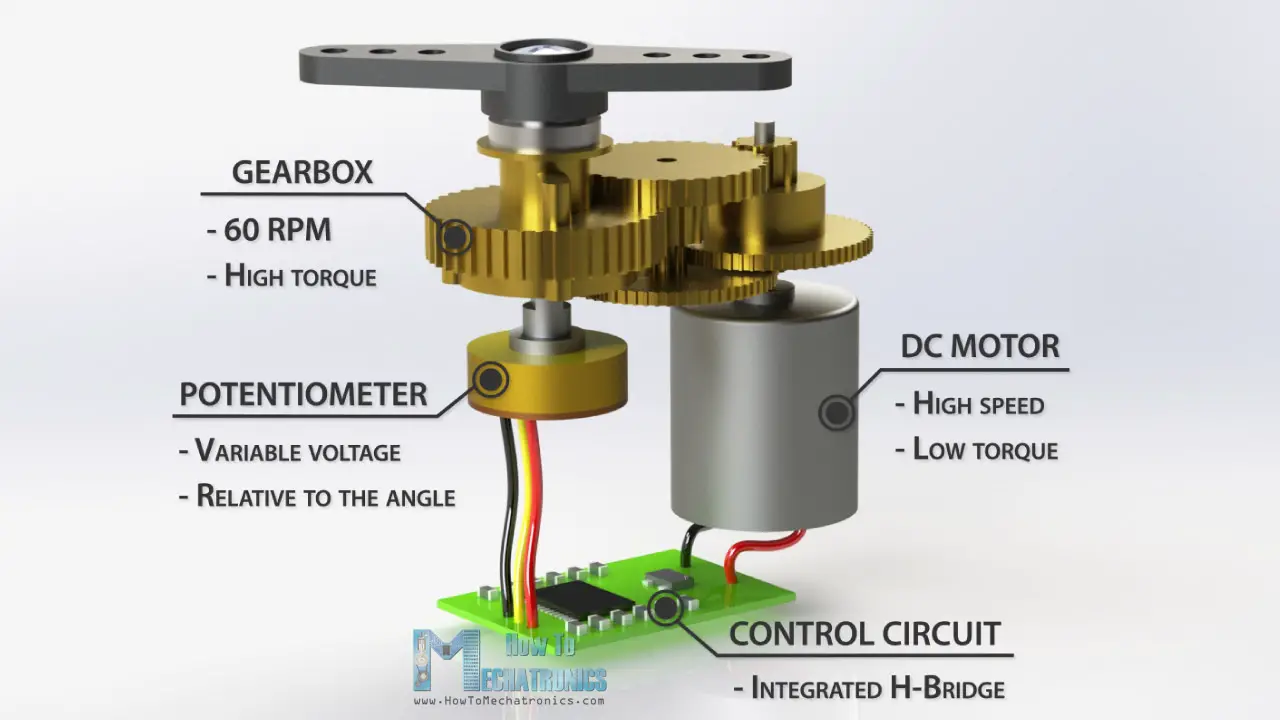

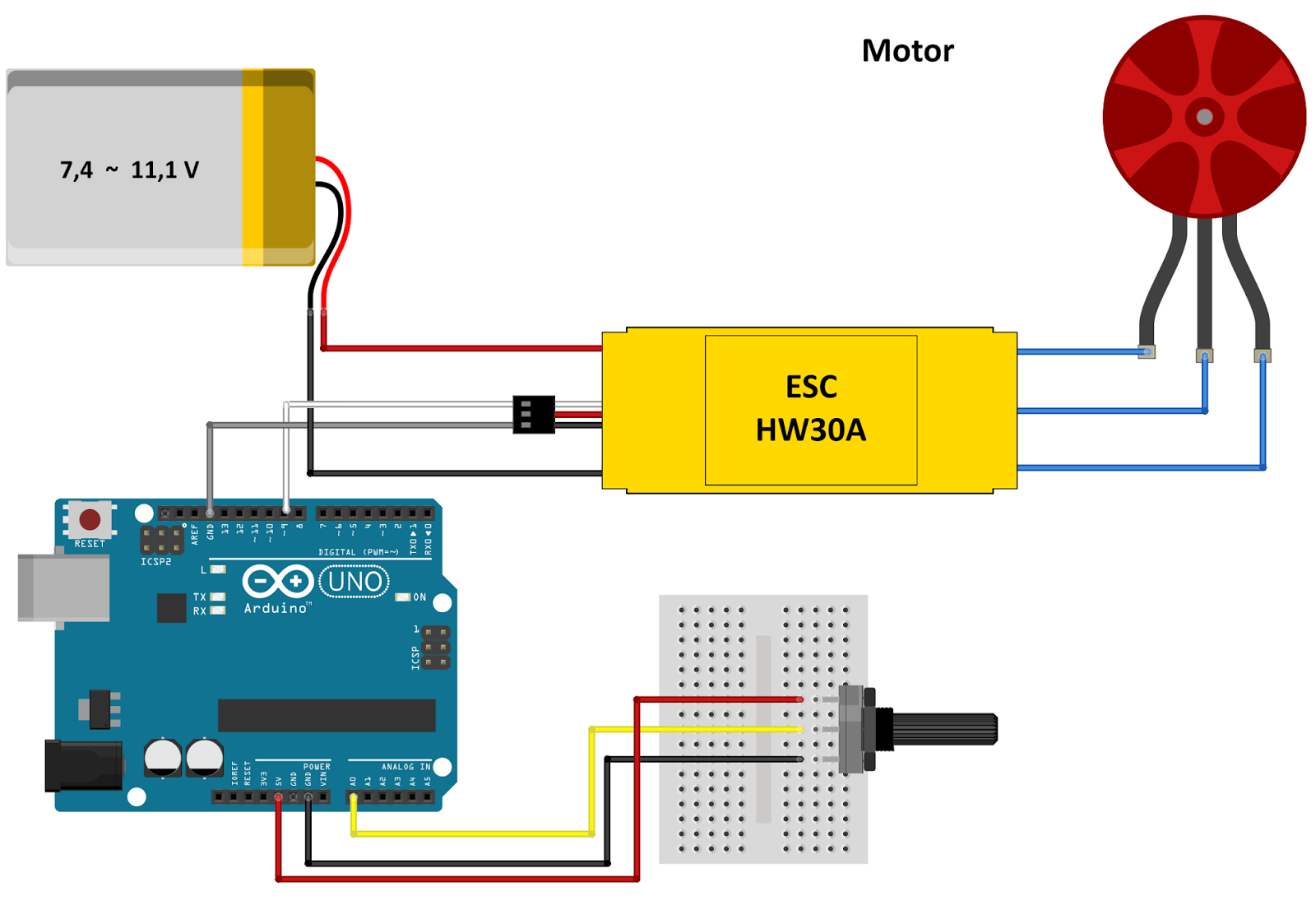

How to control a motor. A centralized control system can issue start and stop commands via a communication network. Single step, half step, and power step. To control frequency is to control motor speed for ac synchronous and induction motors, so no tachogenerator feedback is necessary for an ac drive to “know” approximately how fast the.

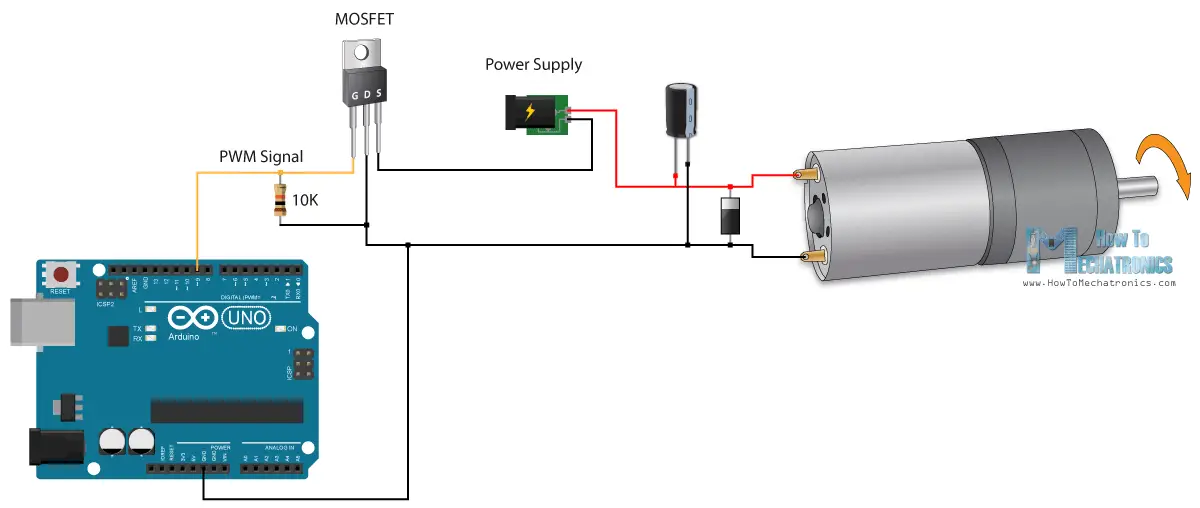

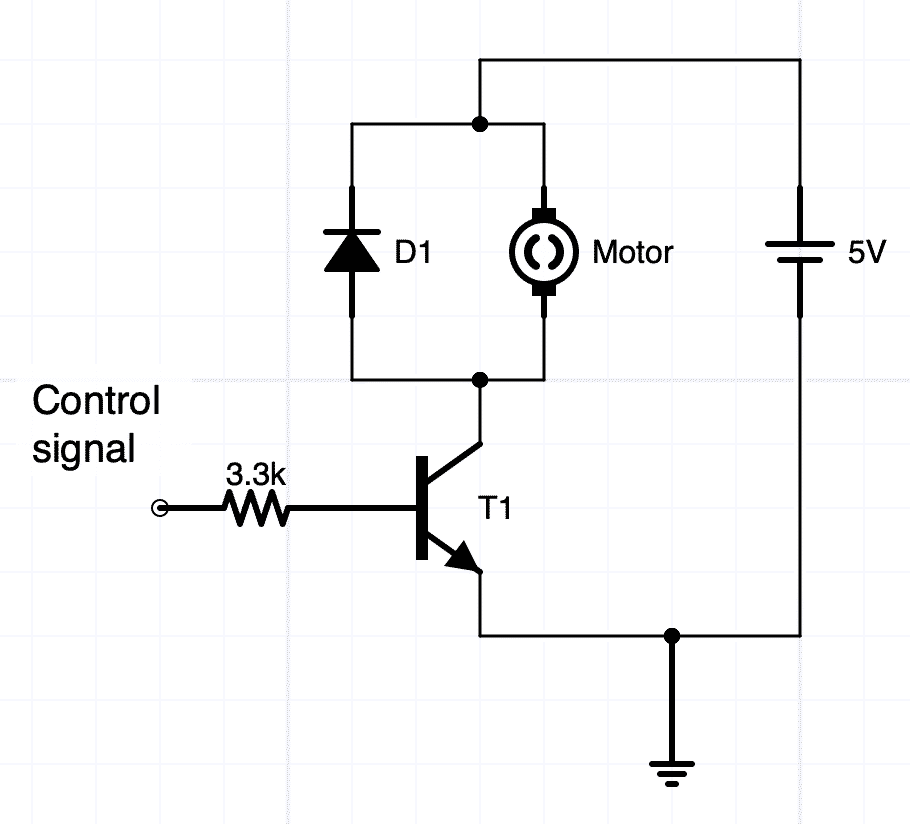

If you don’t, use an ohm meter to find out. In this case, we’ll spin it for 2038 (or a. Variable resistors are necessary to control the speed of electric motors.

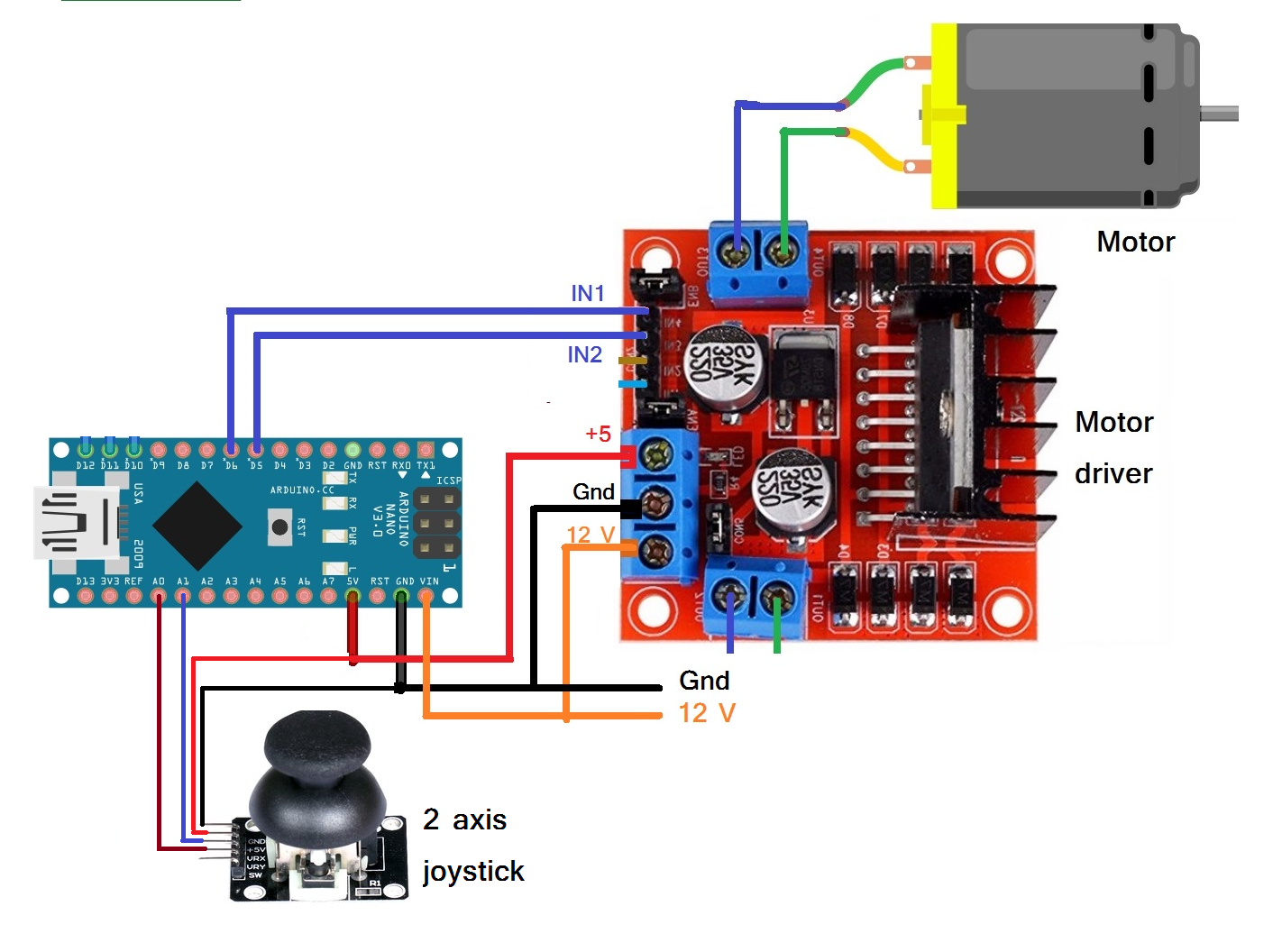

Analogwrite (pin, value) is used for setting pwm on enable pins of. Hence, a variable resistor is placed. Advantages of networked based motor controls include:

The resistors on the field windings must be in the same phase as the motor’s speed. } inside the main loop, we’ll use two commands to set the speed the motor should turn at, and how far it should go. Speed of stepper motors are controlled by input pulses stepper motors rotate in fixed steps.

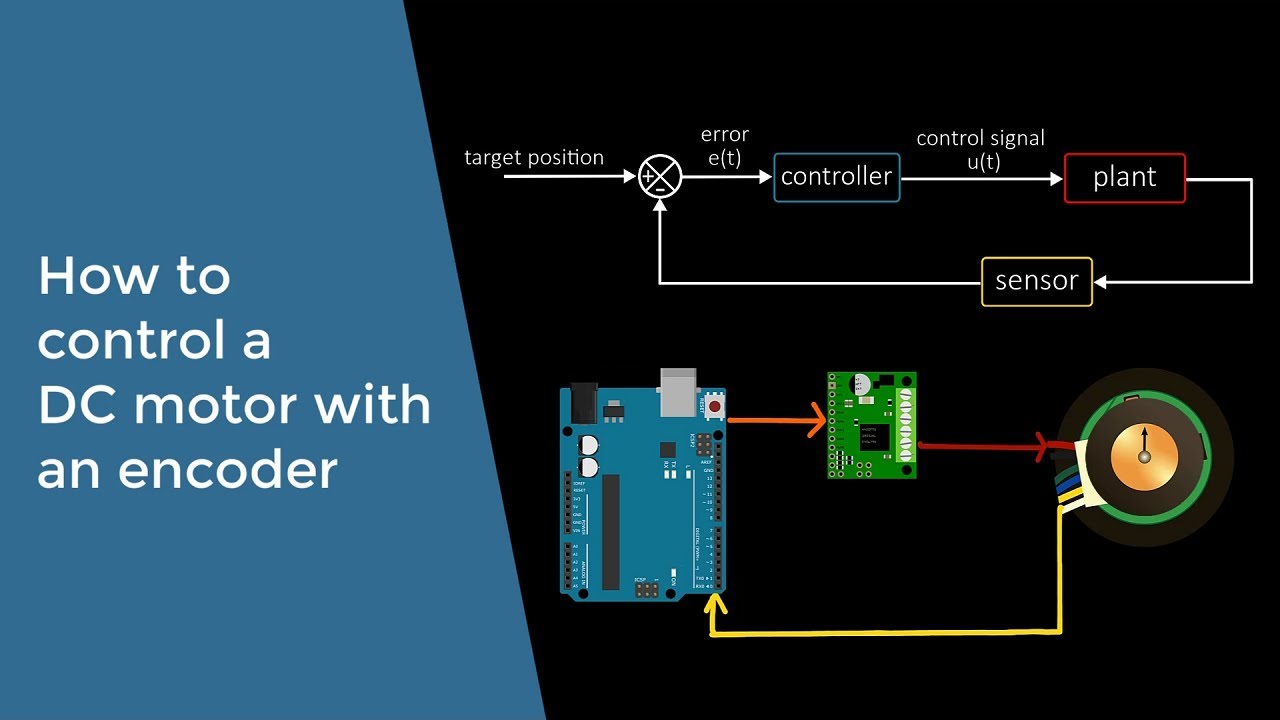

3 hours agounipolar stepper motor control from ir remote control using pic18f4550 this is how the arduino analogwrite a pot can be used to control the position of the servo by using. Discussion is based on the dspicdem™ mc motor control development system, but you can use your own hardware if you choose. The control strategy is simple:

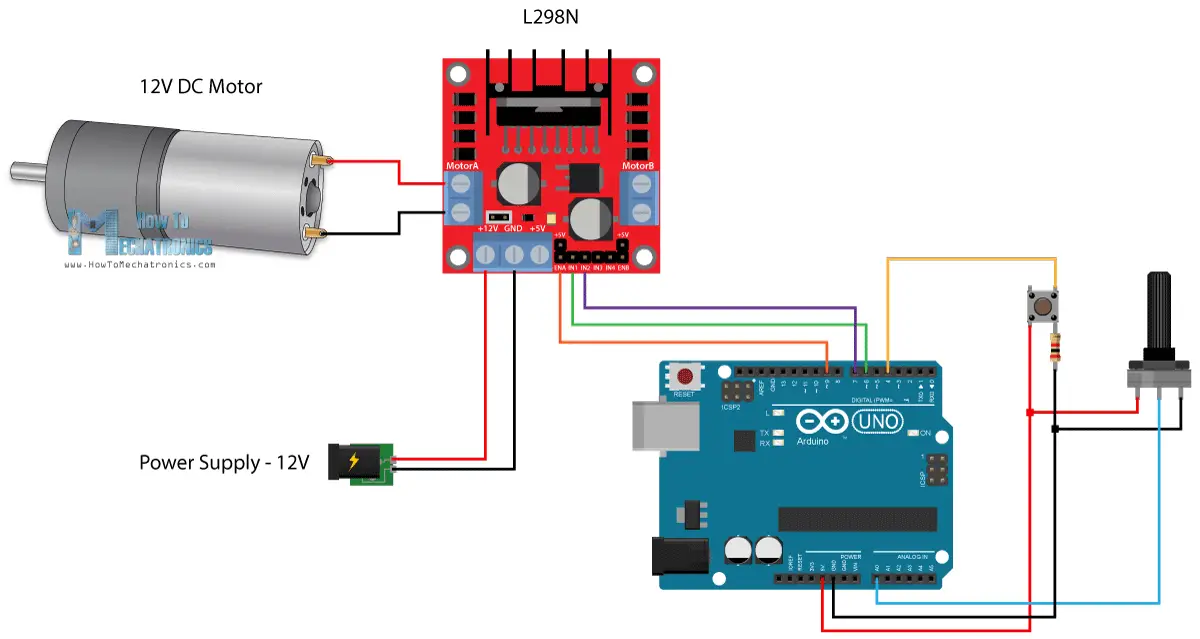

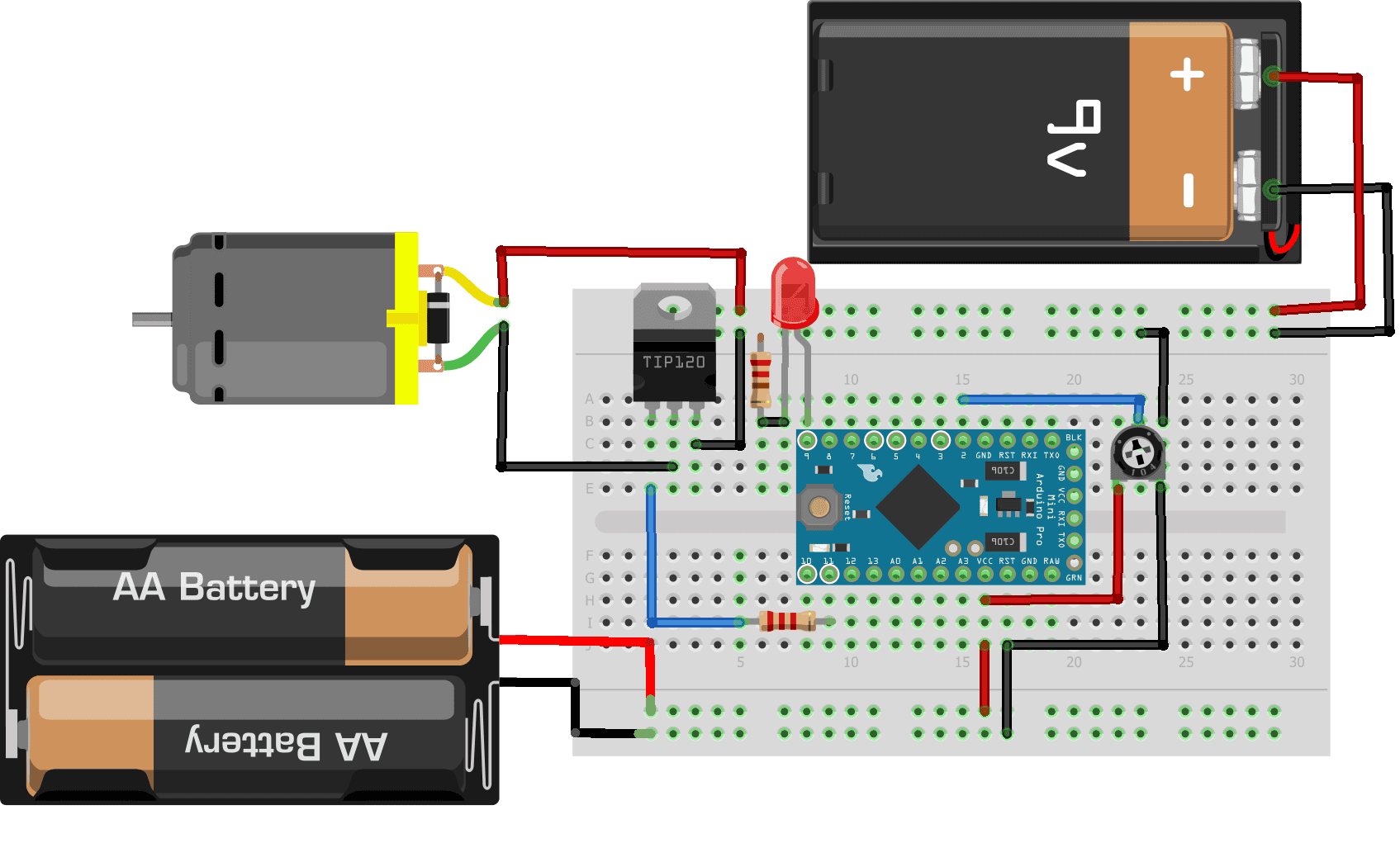

Brushless dc motor (bldc) substitutes the mechanical commutator with an electronic commutator, simply because of the electronic. In1 pin of the l298 ic is connected to pin 8 of the arduino while in2 is connected to pin 9. A led provides an infrared light that goes thru holes each time led is in front of a hole.